Drinking Water Treatment

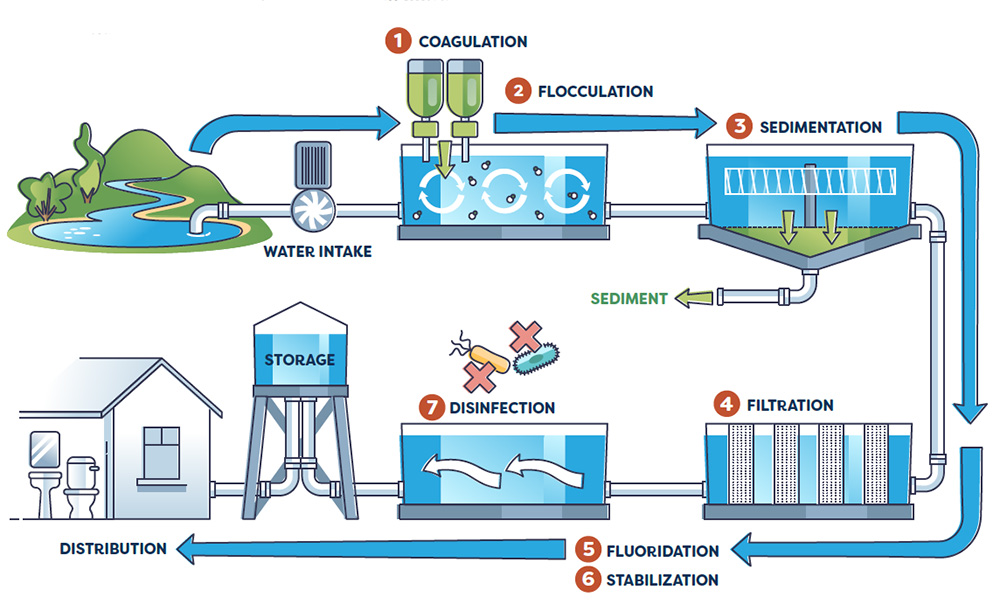

Conventional Water Treatment Process

Longmont follows a process of conventional water treatment, outlined below. More information about our drinking water can be found in the annual Water Quality Report.

1. Coagulation

Aluminum salts, powdered activated carbon and chemicals called polymers are mixed with the water to make the particles in the water stick together and to remove the taste and odor compounds.

2. Flocculation

The coagulated particles are slowly mixed so that they can collide and form larger particles, known as “floc.”

3. Sedimentation

Next, the water moves into a large tank where gravity does the work—the clumps of particles (called “floc”) slowly sink to the bottom, where they can be removed.

4. Filtration

Water is passed through filters made of sand and anthracite coal to filter out remaining particles.

5. Fluoridation

Fluoride is added to help prevent tooth decay.

6. Stabilization

Small amounts of soda ash (sodium carbonate) or sodium hydroxide are added to make the water less corrosive to pipes and plumbing.

7. Disinfection

Chlorine is added to kill any remaining bacteria and other disease-causing organisms.

8. Distribution

The finished water is closely monitored as it enters the distribution system to provide a stable pH, which minimizes scale and corrosion in pipes and plumbing. In addition, chlorine residual levels are routinely sampled throughout the system to ensure the quality of the water at all points of distribution.

Drinking Water Treatment FAQs

Both. Water flows by gravity in most cases and where possible, taking advantage of elevation differences between the Nelson Flanders Water Treatment Plant near Lyons, CO and the City of Longmont. However, pump stations are used to maintain pressure in some areas within the distribution system and to provide system redundancy when water storage tanks are taken out of service.

Longmont’s drinking water is primarily sourced from two reservoirs: Ralph Price Reservoir (Button Rock) and Carter Lake. Ralph Price Reservoir has a maximum capacity of 6.65 billion gallons, while Carter Lake holds up to 36.5 billion gallons. Carter Lake serves as a shared regional water supply for several communities, not just Longmont. In addition, the City can also draw water from the South St. Vrain Creek when conditions allow.

After water is treated at the drinking water plant, it’s stored in four tanks located throughout the City before being delivered to homes and businesses. Together, these tanks amount to 26 million gallons of storage. These tanks help keep water service reliable by balancing supply and demand, storing water when use is low and supplying it when use is high. They also help maintain steady water pressure across the system and provide an emergency reserve for firefighting or during power outages. By circulating water through the tanks, the City keeps the system fresh and ensures high-quality water is available whenever you turn on the tap.

Critical water facilities, including treatment plants, pump stations, and

communication systems, are equipped with multiple/redundant utility feeds and

standby generators to maintain operations during power outages.

In the City of Longmont, clay pipes were only installed for sewer pipes and were not

used for drinking water.

City water is continuously monitored, tested daily, and regulated under the Safe Drinking Water Act, ensuring consistent safety and quality. Private wells are not regulated, and owners are responsible for testing and maintenance. For this reason, quality can vary widely depending on local geology and nearby land use.

Filtration aims to remove particles and things you can see under a microscope. Very small and dissolved substances are not removed through filtration. This is why our high-quality source water matters so much! Our sampling indicates that dissolved substances are either not present or far below regulatory standards.

Longmont’s water system does not contain any lead service lines. This determination is based on an extensive records review and a statistically based service line investigation, both of which are described in detail on the City’s website Lead Protection for Longmont Water webpage. The City maintains corrosion control treatment at the water plant to prevent metals from leaching from older household plumbing. Routine testing confirms compliance with all state and federal lead standards.

The City’s source waters are regularly monitored, and testing consistently shows non-detect or extremely low concentrations, well below state and federal drinking water standards.

Fluoride is added in carefully controlled amounts to maintain the recommended level of about 0.7 mg/L, as advised by the U.S. Public Health Service and CDPHE for dental health benefits. Fluoride is dosed at the direction of City Council.

The decision to fluoridate water is made by the City Council, based on guidance from the U.S. Public Health Service and Colorado Department of Public Health and Environment (CDPHE).

Trace amounts of pharmaceuticals and personal care products may be present at very low concentrations, far below levels of health concern. The City continues to support regional research and source protection efforts to minimize these compounds in source water.